ARE YOU READY FOR IMPACT?

IMPACT POWERED BY CORPORATE SOCIAL RESPONSIBILITY

Our commitment to Corporate Social Responsibility (CSR) is a cornerstone of our strategy. It is formalized in a company-wide policy and driven by a dedicated Chief Impact Officer to ensure accountability and integration into every aspect of our operations.

When customers come to us, the journey often begins with a specific driver:

A need driven by supply chain constraints that prevent the production of new batteries

The demand from operations to finally solve the safety risks and costs of accumulating unused batteries.

Environmental goals and national incentives are relayed by sustainability managers and investors to meet Environmental, Social, and Governance targets with a measurable waste reduction.

A desire from after-sales teams to build customer loyalty with reliable and cost-effective repair solutions.

The resulting impact is plenty.

Our role at NOWOS is to provide our partners with the clear, actionable data to prove it, transforming our mutual challenges into a story of social, financial, operational, and environmental success.

“Without them [NOWOS], broken batteries would either be thrown away under warranty or end up in a landfill when out of warranty. Instead, together we’ve given thousands of batteries a second life, extending their use and preventing unnecessary waste. This collaboration is a great example of how working with the right partners can create real impact.” - Swapfiets

YOUR IMPACT QUANTIFIED

Turn your battery maintenance program into a powerful asset for your business goals. We provide the clear, traceable data you need for ESG reports, investor updates, and operational insights through our dashboards.

Circular Economy Contribution: See the exact percentage of parts reused and recycled.

Operational Reliability: Track your repair success rate, proving program effectiveness.

Critical Materials Saved: Quantify the volume of preserved raw materials like lithium and cobalt.

Direct Financial Savings: Understand the total cost savings from avoiding new battery purchases.

For NOWOS in 2024, this means:

-

In 2024, 538 tons of batteries processed at NOWOS enabled:

a 89% repair success rate

lead times reduced by 50%

ride times increased

-

Repairing a battery can reduce your costs from 40-70% vs buying new.

Benefit from safe, compliant and regulated operations, reducing penalities and financial risk.

-

In 2024, we calculated a 98% material recycling efficiency rate, when we combine our repair rate and our recyclers’ efficiency rate.

Of 538 tons of batteries processed, this avoided the mining of

14 200 tons of critical raw materials,

Including 7 200 tons of Cobalt

which would have been required to make the equivalent of new batteries.

-

89/100 on the French Professional Equality Index.

0 Lost-Time Accidents in 2024.

5% of hours dedicated to social insertion in 2024

NOWOS IN NUMBERS

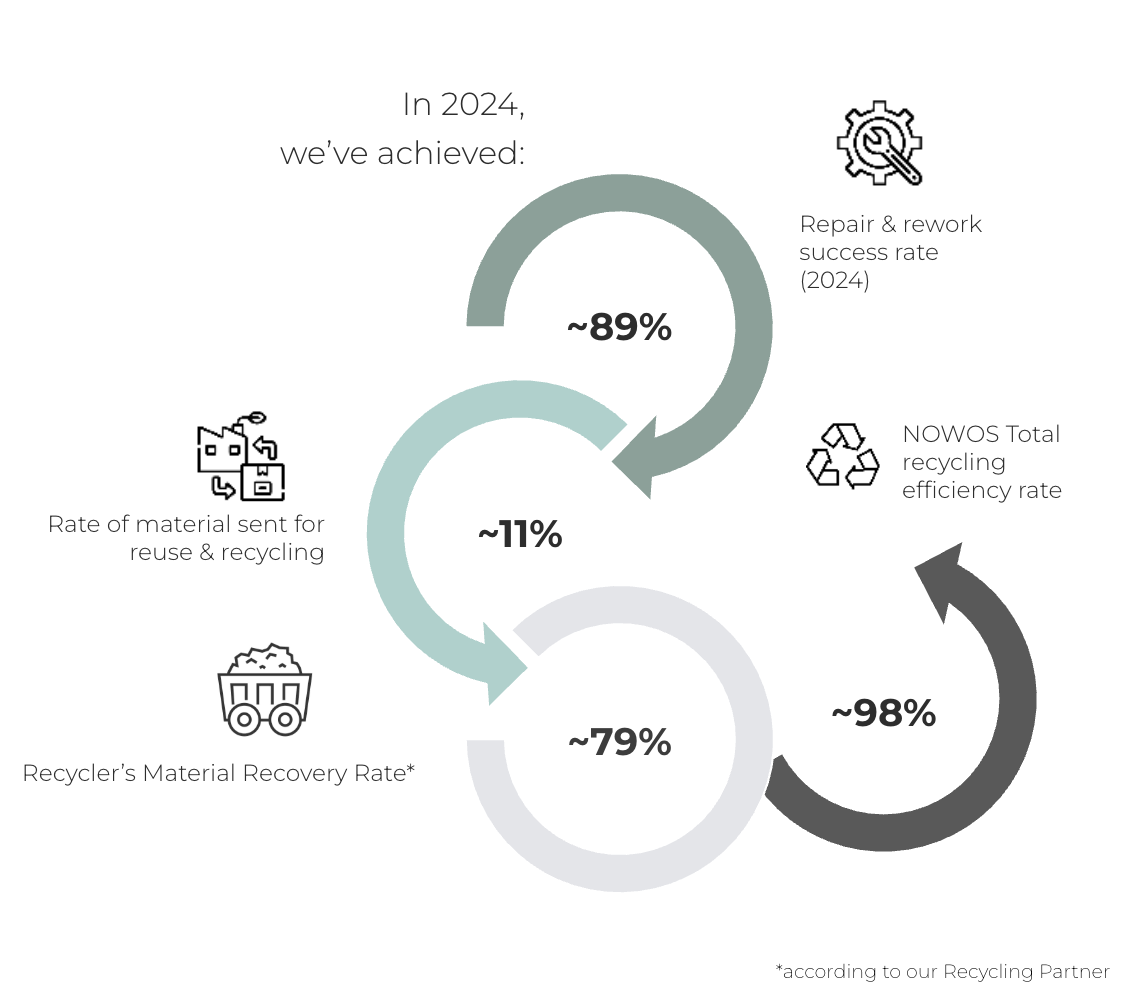

In 2024, we successfully repaired and reworked 89% of all batteries, extending their life and value for our customers.

The remaining 11% were dismantled for the reuse of parts and recycling. Through our recycling partner, who achieves a 79% material recovery rate, we reached an overall 98% Total Recycling Efficiency rate, meaning total recovered materials during the recycling process for these end-of-life batteries.

While 2% of materials are lost in the current recycling process, we are actively working with industry partners on designing next-generation products to close this gap and achieve 100% circularity.

2025 Areas of Action

-

Pillar 1: Emission Reduction

We are actively minimizing our own operational footprint through:

Optimizing Processes: Improving energy efficiency and reducing energy loss at our facilities.

Sustainable Sourcing: Prioritizing sustainable and recycled materials for our packaging and office supplies.

Industrial Waste Management: Tracking and managing all materials to reduce waste from our processing.

Low-Carbon Logistics: Using low-emission vehicles with EURO 5 or EURO 6 standards, and optimizing transport routes through centralized hubs.

-

Pillar 2: Increasing Avoided Emissions

We help our customers extend battery life and reduce the need for new production by:

Promoting Circularity: Partnering with manufacturers to integrate battery servicing and life-cycle opportunities into their business plans.

Supporting Battery Durability: Developing monitoring tools, like the Battery Passport, to help customers track battery health and prevent premature wear.

Implementing Second-Life Uses: Preparing still-functional packs for reuse, such as stationary energy storage. Read more.

Reusing components from unrepairable batteries as much as possible.

-

Pillar 3: Critical Material Avoidance

Our mission is to reduce the demand for newly mined critical materials like lithium, nickel, and cobalt and encourage reuse and repair. We do this by extending the life of materials already in circulation.

In 2024, processing 538 tons of batteries allowed us to avoid the mining of 14 200 tons of new materials. This included 7 200 tons of Cobalt and 25 tons of Lithium.

We are continuously working to refine these calculations and expand our impact.

By enabling customers to assess their own Critical Raw Materials impact, we help create a more transparent economy.

At NOWOS, we're actively working towards a sustainable future by aligning our mission with the UN Sustainable Development Goals. We focus on three primary goals where we can make the most impact.

Primary Goals: Our Core Impact

SDG 12: Responsible Consumption & Production

SDG 9: Industry, Innovation & Infrastructure

SDG 7: Affordable & Clean Energy

Secondary Goals: The Broader Impact

SDG 11: Sustainable Cities & Communities SDG 13: Climate Action

SDG 8: Decent Work & Economic Growth

Our CSR Framework

Governance & Ethics

Strategic Oversight Our operations are overseen by a dedicated Supervisory Board, which provides strategic guidance and ensures the highest level of accountability across the organization.

Stakeholder Engagement We maintain transparency and foster open dialogue with our financial partners through regular investor and shareholder meetings, where we discuss our strategy, performance, and long-term impact.

Ethical Operations: Our day-to-day business is guided by a formal Code of Conduct.

Our People

The health and safety of our team is paramount, managed through a formal Health & Safety policy and a comprehensive risk assessment framework.

We champion a diverse and inclusive workplace with formal policies against discrimination and for the employment of persons with disabilities.

We invest in our team's potential through structured professional training.

Environment Management

To ensure continuous improvement, we are on track to calculate our carbon emissions emitted and avoided for the third year in a row, thanks to a collaboration with Via-ID’s impact program. The avoided emissions are calculated each year using Carbone 4’s Net Zero Initiative methodology.

In 2025, we launched a process with The Rainbow Standard to assess our product’s footprint and avoidance with an extensive Life Cycle Analysis.

Notification on Carbon Accounting

A Note on Emission Credits

Please be aware that all emission credits from products we repair or service are registered by NOWOS. These credits are part of our certified climate protection project (Rainbow Registry, Project ID: RIV-2025-PROJ-123) and are not transferable to clients. [link]

Our Climate Protection Project: When you use our services, you're supporting a certified climate protection project. NOWOS registers all emission credits from our repair work with the Rainbow Registry (Project ID: RIV-2025-PROJ-123) as part of our company's commitment to sustainability.

Q: Do I receive the carbon credits when I get my product repaired?

A: No. NOWOS registers all emission credits from our repair services as part of our own certified climate protection project. This is documented in the Rainbow Registry (Project ID: RIV-2025-PROJ-123) and allows us to centralize our environmental impact.

Q: Since you are repairing our batteries, shouldn't our company receive a share of the carbon credit revenue?

A: This question highlights the important difference between a product and a project in the voluntary carbon market.

Here’s a simple breakdown:

Credits are Awarded to the Project, Not the Product. In the voluntary carbon market, credits are not tied to an individual product (like your battery). They are awarded to the certified project that makes the emissions reduction possible. Under the Riverse methodology (Project ID: RIV-2025-PROJ-123), our advanced repair facility is the project.

Credits Incentivize the Solution. The goal of this system is to incentivize and fund the creation of specialized facilities like ours. These facilities are the true bottleneck in creating a circular economy, and the carbon credits help us build and scale this vital work.

You Receive a Different, Powerful Value. Your company receives a direct and significant benefit: measurable Scope 3 emissions reductions. By choosing to repair rather than replace, you get to claim these reductions on your own environmental ledger, which is a powerful asset for your company's sustainability goals and reporting.

Q: But what about Tesla? They get credits because people buy their cars. Why is this different?

A: That's a common comparison, but it's actually a different system. Tesla's credits (in that example) often come from a compliance market (like California's), which operates under different, government-mandated rules. We operate in the global voluntary carbon market, where the rules are designed to fund specific, registered projects like our repair facility. The analogy isn't relevant here.

Q: What if we decide to repair our own batteries to claim the credits ourselves?

A: You could, but it's important to understand what that entails. To claim carbon credits, you would need to become a certified project operator yourself.

This involves:

Operating your own industrial repair facility.

Complying with the full, complex Riverse methodology.

Implementing rigorous data monitoring and tracking.

Undergoing (and paying for) regular, independent third-party audits.

Managing the official registration and issuance process.

This requires significant technical and operational investment.

Our service allows you to gain the core environmental benefit (your Scope 3 reductions) without taking on this complexity. It is therefore fair, and standard practice, for NOWOS as the entity enabling and executing the project to retain the credits.